SPIKE Tool Maintenance

It is critical to ensure that the hammer cap (part #1shown below) is secure and tight at all times when SPIKE is in use. A loose hammer cap can lead to spurious firing of the tool. This should be checked before each tool use.

Spike Tool Inc. recommends maintenance of the SPIKE Tool every two years. The internal parts of the SPIKE Tool will wear with continued use over time or may have reduced functionality due to operating in harsh field environments. Spike Tool Inc may not be able to support tools after ten years from purchase. During this ten year period it is highly recommended the tool be sent to SPIKE Tool Inc bi-annually for maintenance.

Ship your tool to your Distributor for inspection and overhaul by the manufacturer. An estimate for repair and maintenance will be provided for your approval before commencing work. After your approval to proceed with the maintenance is received your tool will be completely refurbished and shipped back to you promptly. Should an urgent need arise while your tool is under maintenance SPIKE Tool Inc. can send you a loan tool.

Your SPIKE Tool will be restored to peak operating performance. There is a one-year manufacturer maintenance warranty, the same as a newly purchased tool.

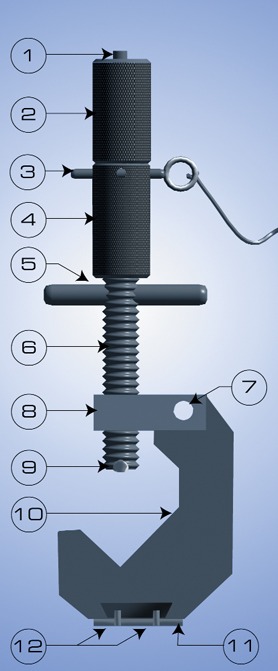

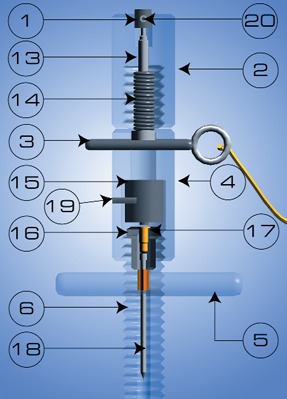

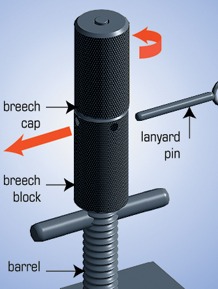

SPIKE Parts Description

- Hammer Cap

- Breech Cap

- Lanyard Pin & Lanyard

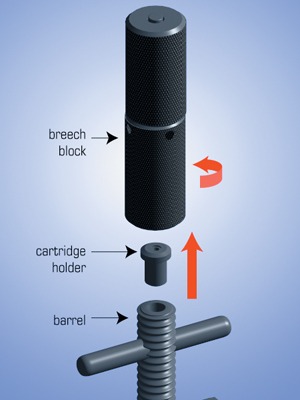

- Breech Block

- Barrel 'T' Handle

- Barrel

- Tapped Mounting Hole for 25mm Ball Stud (Limit: 20kA) or Split Bolt Connector 1/0 AWG Copper (Limit: 10KA) for Bonding to Ground

- Barrel Guide

- Barrel Safety Stop

- Cable Clamp

- Safety Striker Plate 3/8"

- 2 Allen Screws 5/32"

- Hammer

- Hammer Spring

- Firing Pin Assembly

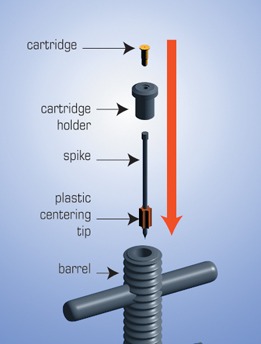

- Cartridge Holder

- Power Load

- Spike

- Allen Screw 1/8"

- Allen Screw 5/64"